https://egyptmanchester.wordpress.com/2018/01/19/the-use-of-steatite-in-ancient-egypt/

The Use of Steatite in Ancient Egypt

A guest blog on the well-attested stone known as steatite from experimental technologist Matt Szafran…

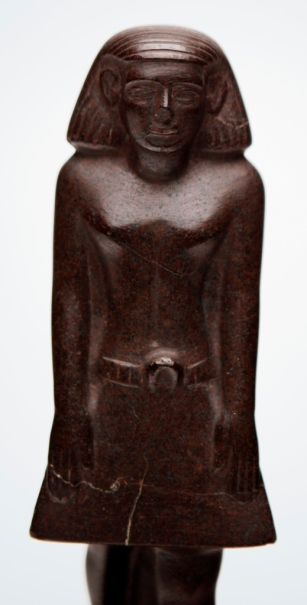

Statuette of Neb-iu, the 'spinning statue'. Photo: Paul Cliff.

Steatite, sometimes called 'soapstone', is a green/grey/brown coloured metamorphic rock made from talc-schist which will naturally darken as it oxidises. This colouration can cause steatite to sometimes be confused with serpentinite – a different and unrelated metamorphic rock with a hardness of Mohs 3-5, which is also used for statuary (such as the Manchester Museum's world famous 'Spinning Statue' – accession number 9325 (left)). Steatite occurs in the Eastern Desert at sites such as Wadi Abu Qureya and immediately north and south of Wadi Barramiya. In its natural state steatite is a heavy rock and its high talc content makes it very soft – with a hardness of only Mohs 1. Bronze has a hardness of Mohs 3, horn and bone have a hardness of Mohs 2.5 and flint has a hardness of Mohs 7; meaning that steatite can very easily be worked with even the most basic of tools – often yielding very finely detailed results. Whilst it's used in multiple cultures (up to and including modern times), in an Ancient Egyptian context steatite was used in both Predynastic and Dynastic periods but it does appear to be limited to smaller statues, shabtis, beads, amulets and seals. Whilst large sections of steatite could have been quarried, there are no extant examples of use for larger statuary or other larger carved objects.

In its raw state the softness of steatite make it extremely easily damaged, and simply wearing or using a carved object would damage the carved detail. Steatite has an interesting property, when it is fired it will convert from steatite into enstatite. Unlike steatite, enstatite has a hardness of Mohs 5.5 which is close to that of granite – making it extremely hard wearing and resistant to damage, whilst still retaining its carved detail. Steatite has also been glazed since the Predynastic era for objects such as beads and amulets. Glazing can be achieved in one of two ways; either the object can be buried in a glazing medium during firing (a process called cementation), or it can have a glaze applied to its surface prior to firing. These glazes would be very similar to Egyptian faience and be made from powdered quartz and copper (the latter providing the blue/green colour).

Firing at a temperature of ~950°C will cause steatite to dehydrate and crystallise into enstatite. Clay will begin its vitrification process ~800-900°C and firing will generally require temperatures in excess of 1100°C , therefore the steatite to enstatite conversion can be achieved using similar technology as is required for firing clay objects. A wood fuelled open fire can easily reach temperatures exceeding 1100°C, and can be used for firing ceramics and also for converting steatite to enstatite. However as this requires a large volume of fuel this is unlikely to have been the method used in Ancient Egypt, where wood has been a scarce resource in various periods. A kiln requires less wood to reach firing temperature than an open fire; however it still may not have been the fuel of choice. Ethnographic studies have shown that modern Egyptian and Sudanese cultures are using dung fuelled kilns for the firing of pottery. This is therefore likely to have been something which was undertaken in ancient times. Unlike wood an open dung fuelled fire will only reach a maximum of ~650°C and will not reach the temperature required for the steatite to enstatite conversion. Therefore if dung was used as a fuel it would require a kiln to reach the necessary temperature for conversion.

Perhaps the only factor which prevented the production of larger steatite objects in Ancient Egypt was simply a lack of available technology and materials to fire large objects and convert them into enstatite. An unfired statue would be vulnerable to damage and if left outside would be abraded very quickly by nothing more than the sand blown on the wind.

Certain descriptions of the use of fired steatite for statuary imply that it is a less expensive alternative for individuals who could not afford, or did not have access to, granite or the craftsmen to work it – as once these statues have been fired they would then have an appearance and feel similar to granite. Whilst this is likely the case for certain examples, it would be naive and cynical to assume that this was the only reason to choose steatite over an alternative material.

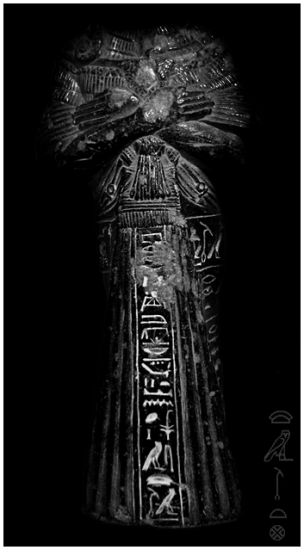

Shabti of Khaemwaset (UC 2311). Photo: Matt Szafran

The Petrie Museum holds an extremely finely carved shabti of Khaemwaset (UC2311). This shabti has intricately carved fabric folds of everyday wear (rather than the more typical wrapped 'sah-iform' shape commonly employed for shabtis), a beaded collar, the Sem-Priest side-lock hairstyle and hieroglyphic inscription. Prince Khaemwaset was the fourth son of Ramesses II, was the crown prince briefly between the 50th and 55th year of his father's reign and High Priest of Ptah. He can therefore certainly be thought of as being an 'elite' who had access to the highest quality and 'elite' only materials (such as granite or basalt), and who had access to the best craftsmen and the wealth to commission them. Therefore the use of steatite for his shabti was a deliberate choice neither governed by affordability nor the lack of access to materials such as granite.

There is no simple answer as to why steatite is used as a sculpture medium, and any such statement should be treated with caution. It is highly likely that in some cases the use of steatite was indeed because the more 'elite' materials were unaffordable or unavailable, however in in other cases the choice to use steatite was very deliberately made because of the material's ability to be intricately carved and fired to produce an object which could not be created in another medium.

Further Reading

Connor, S, Tavier, H and De Putter, T. 'Put the Statues in the Oven: Preliminary Results of Research on Steatite Sculpture from the Late Middle Kingdom'. Journal of Egyptian Archaeology 101 (2015).

-- Sent from my Linux system.

Quran for Children is an online platform dedicated to providing engaging and interactive Quran learning for kids. The website offers structured courses focusing on Quran recitation, memorization, and understanding, tailored to suit children of all ages. With experienced teachers and a flexible online learning environment, Quran for Children aims to nurture a love for the Quran while instilling Islamic values in young learners.

ReplyDeleteFor more information, visit my website.

https://quranforchildren.com/